A “tip” in a coal mine refers to a site where waste material, known as spoil or overburden, is stored after it is excavated from the mine. When coal is extracted from the ground, large amounts of non-coal material—rocks, soil, and other waste—are inevitably unearthed. This material has no economic value, so miners need a designated area to discard it, and these areas are known as coal tips, spoil heaps, or mine tips.

The Role of Tips in Coal Mining Operations

In the coal mining process, tips are essential for waste management. When coal is mined, only a fraction of what is extracted is coal; the rest is composed of rocks, shale, clay, and other by products that miners separate out. Tips provide a convenient solution, as they allow the mine operators to keep the working areas free from obstructive waste material while maintaining a clear path for both equipment and personnel.

The Formation of Tips

Coal tips are formed through a process called tipping. Tipping involves transporting the overburden or waste material to the tip site, which is typically close to the mine. The material is then dumped or piled up in large mounds, sometimes reaching considerable heights. Tips can be formed using various methods, depending on the topography of the land and the specific requirements of the mine. Some tips are layered systematically to create stable formations, while others are simply built up over time as more material is added.

In many instances, tips are placed on steep hillsides or valleys near the mine, especially in areas where flat ground is scarce. However, these locations can present a risk to nearby communities and the surrounding environment. Over time, some tips have been prone to instability, especially under certain weather conditions.

Types of Tips and Their Variations

There are several different types of coal tips, each with unique characteristics. The most common types include:

- Slope Tips: Built on sloping land, these tips use the natural incline of the terrain to help stabilize the waste pile.

- Cone Tips: Constructed in a conical shape, these tips are often formed by allowing waste to accumulate naturally around a central dumping point.

- Ridge Tips: These tips follow the ridge of a hill or slope and are often spread over a longer distance to distribute the weight and reduce the risk of collapse.

Each type of tip has its own structural considerations. For example, ridge tips spread out the material to reduce overall stress, while cone tips, although efficient in terms of space, may create a central point of weakness if not managed carefully.

The Environmental and Safety Risks of Tips

Coal tips, while practical, can present environmental and safety risks, particularly if not managed or monitored properly. The two most significant risks associated with coal tips are tip slides and spontaneous combustion.

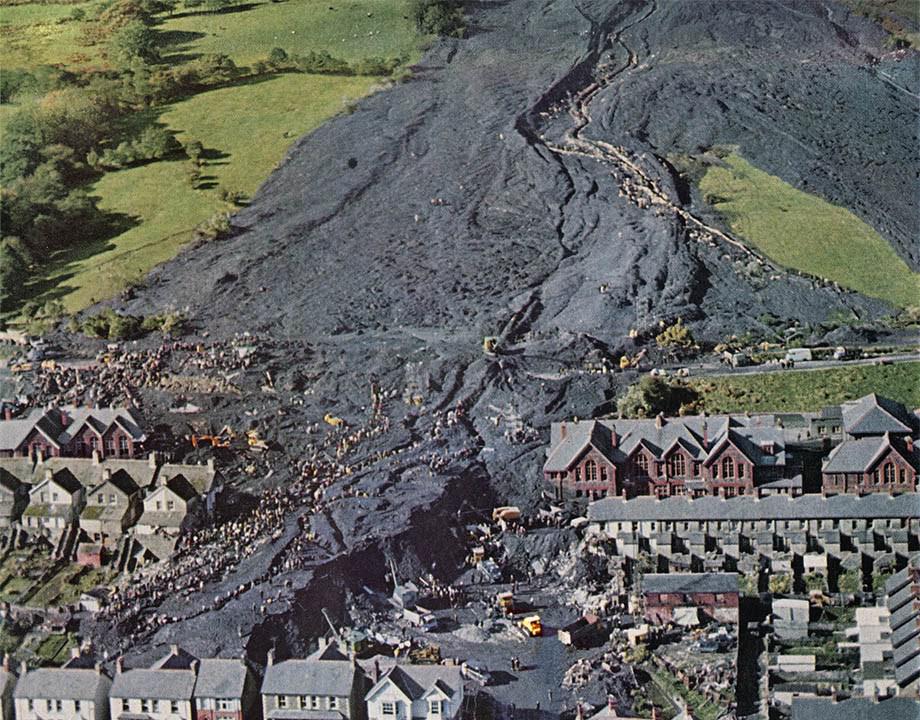

- Tip Slides: A tip slide occurs when the waste material on a tip loses stability and collapses, potentially causing a landslide. This can happen due to factors like heavy rainfall, poor drainage, and soil saturation. In coal mining history, one of the most devastating tip slides occurred in Aberfan, Wales, in 1966. Heavy rains caused a coal tip to collapse, engulfing a school and several houses, resulting in the tragic loss of 144 lives, most of them children.

- Spontaneous Combustion: Tips are often composed of various materials, including coal dust, which can sometimes spontaneously ignite. When coal and other carbon-rich materials are exposed to oxygen, they can oxidize and produce heat. If this heat isn’t dissipated, it can build up and eventually cause the tip to ignite, leading to fires that are difficult to control and harmful to both the environment and human health.

In addition to tip slides and spontaneous combustion, coal tips can also impact the environment through soil and water contamination. Rainwater can wash harmful materials from tips into nearby rivers and soil, introducing toxic substances such as heavy metals into the ecosystem.

Tip Management and Safety Measures

Due to the risks associated with coal tips, the mining industry has developed various strategies for tip management to ensure stability and safety. Modern tip management practices involve assessing the geotechnical properties of the tip site, such as soil composition and slope stability. Engineers also evaluate drainage systems and use retaining walls or other supports to reinforce the tip structure.

In areas where tips are situated near populated communities, additional monitoring is put in place. For example, geotechnical sensors and satellite technology can monitor tip stability and detect early signs of movement. Regular inspections are conducted, and emergency plans are established in case of a tip collapse.

In many countries, coal tips are subject to strict regulations and inspections to mitigate the risks of tip slides and spontaneous combustion. Some areas even mandate the removal or remediation of coal tips to eliminate potential hazards altogether. The lessons learned from past disasters, such as the Aberfan tragedy, have shaped modern practices and regulations to prevent such incidents from recurring.

Reclamation of Tips

Once a coal mine has been closed or a tip has reached capacity, efforts are often made to reclaim or restore the land. Reclamation involves reshaping the tip and covering it with topsoil, followed by the planting of grass, trees, or other vegetation to stabilize the surface. In some cases, former tip sites are transformed into parks, recreational areas, or even natural habitats, contributing positively to the local environment and community.

Reclamation not only improves the aesthetic value of the landscape but also helps prevent erosion and runoff issues. In some cases, former coal tips are also used as sites for renewable energy projects, such as wind or solar farms, contributing to the ongoing shift towards sustainable energy solutions.

Conclusion

In coal mining, tips serve a critical function by providing a safe and organized place to store the massive amounts of waste generated during coal extraction. While essential, these tips can pose significant risks to both human safety and the environment if not managed properly. Through modern engineering practices, regulation, and land reclamation, the mining industry is better equipped to mitigate the risks associated with tips.